George Grant & Tanner Bailey | GGSPro Technical Specialist

As growers, we are faced with a myriad of obstacles that must be overcome to produce a quality crop. Regardless of scale, growers will eventually experience pests and diseases that must be treated. The treatment and management of pests and diseases represent a large fraction of the cost and time within the overall production scheme. Traditional approaches utilize hydraulic spray equipment with large volumes of water to treat the desired area. In this scenario, the efficacy of an application is determined by the applicator’s skill level and the quality of equipment being used. With ever-increasing labor and input costs, there is no room for wasted dollars on the greenhouse floor. In this article, we will highlight the use of Ultra-Low Volume spray technology and how it can benefit your operation in terms of labor, costs, and crop quality.

What is ULV?

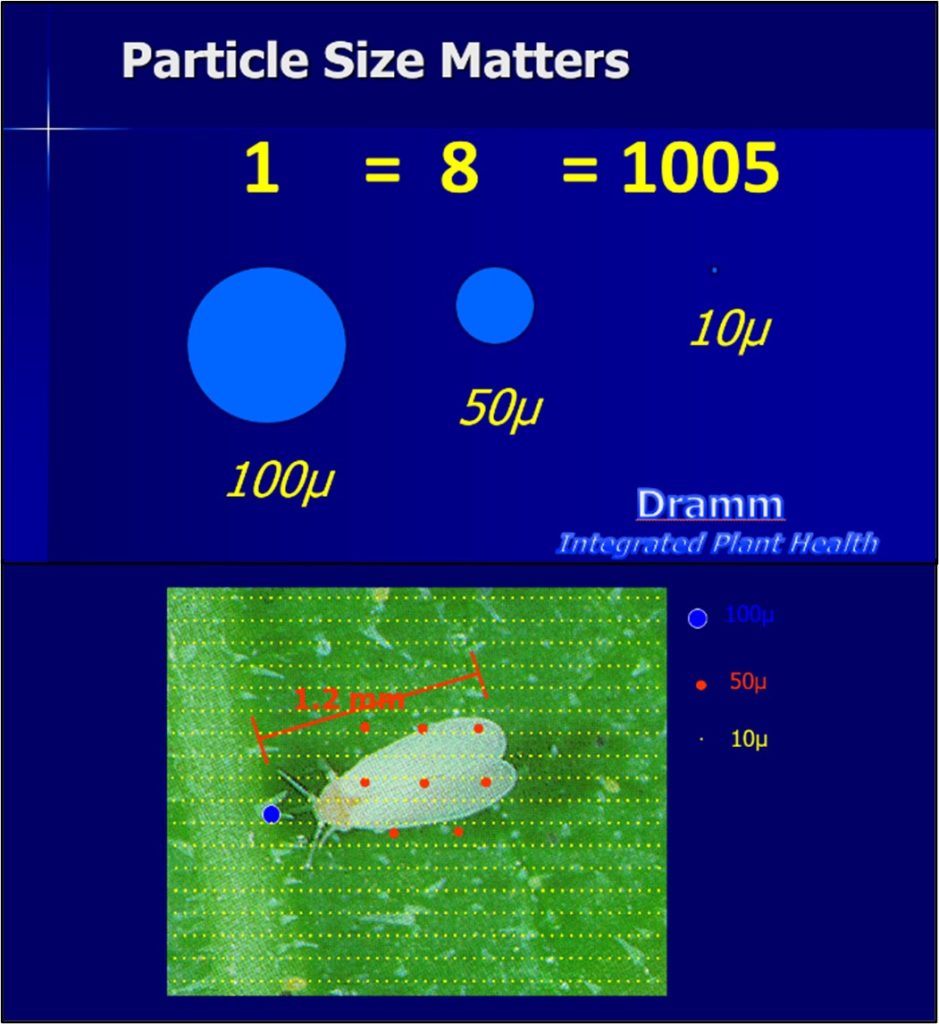

Ultra-low volume (ULV) treatment, also known as fogging, works by atomizing spray particles to significantly reduce the volume of spray utilized when applying chemicals. Small particle sizes enable products to be applied with excellent uniformity and coverage within both the upper and lower portions of the crop canopy that may otherwise be missed by traditional hydraulic sprayers. Fogging equipment micronizes billions of pesticide-containing particles and disperses them to all surfaces within the greenhouse. In the next sections, we will look at the advantages and limitations of ultra-low volume technology followed by an overview of the equipment options available through Griffin Greenhouse Supplies.

Advantages of Ultra-low volume treatment:

- Superior coverage – very small particle size and high-pressure delivery combine for thorough coverage of the plant canopy and greenhouse.

- Labor savings – growers find cold foggers and thermal foggers to be about ten times faster than hydraulic spraying.

- Reduced pesticide exposure – (auto foggers only) the applicator is not in the greenhouse at any time during the pesticide application.

- Greatly reduced water volume – auto foggers, for example, require only 2-4 liters to treat 10,000 sq ft of greenhouse space for most chemicals. Dry foliage decreases foliar disease risk and the potential for runoff.

- Reduced pesticide usage – most growers feel they make fewer pesticide applications over the course of a year due to improved effectiveness.

- Reduced potential for visible residue and phytotoxicities – fogging avoids pesticides “puddling up” on plant surfaces, eliminating visible residue and decreasing the risk of phytotoxicity. Important: Heed all label cautions about potential phytotoxicities, don’t assume that low-volume applications will eliminate the potential for damage.

Limitations of Ultra low-volume treatment

- Chemical selection – some pesticides have labels that forbid the use of low-volume applicators. Horticultural oils, microencapsulated formulations, and other pesticides are not recommended through certain machines. Please request GGSPro’s “Do Not Fog” bulletin after purchasing your Dramm fogger through Griffin.

- Plant growth regulators – further research needs to be conducted on applying PGRs through ULV equipment, foliar PGR treatments are still being applied by high-volume spray equipment.

- Spot spraying – it is not possible to treat individual benches or groups of plants with low-volume equipment. Greenhouses with vegetables and herbs must be treated with products approved for those crops, greatly reducing pesticide choices.

- Equipment costs – on average, low volume equipment is more expensive upfront to purchase than hydraulic spraying equipment.

Types of Foggers Available

AutoFog™ – Several models are available with coverage from the smallest greenhouses up to 70,000 sq ft with HAF fans. Fully automated operation with timers to begin and end the application time. These units produce the smallest particle size of all the Dramm foggers.

PulsFOG™ – Gasoline engine-driven thermal foggers are the choice when large areas need to be fogged quickly. A BioPulsFOG™ is also available for applying heat-sensitive chemicals, including many microbial insecticides and fungicides.

Turbo Hybrid Coldfogger™ – A directed low-volume applicator that comes with multiple nozzles to match particle size with the job at hand. Backpack unit that requires an extension cord for operation. Ideal for small to medium-sized fogging needs.

| Fogger Type | Particle Size (microns) |

| Conventional Hydraulic Sprayer | 100-400 |

| Coldfogger/Turbo Hybrid Fogger | 30-60 |

| Pulsfog/BioPulsfog | 10-20 |

| AutoFogger | 0.5-10 |

In closing, utilizing ultra-low-volume equipment offers many benefits to growers. These come in the form of decreased worker exposure to pesticides, improved control through smaller particle sizes leading to greater and more uniform coverage, decreased labor costs, reduced pesticide usage, and more. Additionally, when a grower purchases a fogger through Griffin, GGSPro can create a custom fogger chart for their unique operational needs outlining chemical rates for a wide range of fungicides and insecticides.

Note, not all products are registered in all states. Some pesticides are restricted use in some states or regions and not others. It is the responsibility of the applicator to read and follow all label directions, remembering that labels may change. Other products may be safe and effective. Rates, application methods, and edible status are detailed in our GGSPro Insecticide & Fungicide Guides. Griffin also offers the 5th Edition GGSPro Technical Reference Guide in both English and now Spanish versions. This valuable resource outlines a wide range of pest control options along with information on pollinator safety, BCA’s, scouting, weed management, plant lighting, nutrition, water quality and more!